Can we help? 01942 521919

Contact us Recycling is one of the easiest and most recognisable ways to go green, and many materials can be recycled, including cardboard. Whilst cardboard boxes may not seem like the most eco friendly option for packaging materials in the first instance, the corrugated cardboard they are made from can be used and recycled.

In fact, more than 80% of corrugated packaging in the UK is recycled, a higher rate than for any other major packaging material. Such effective recycling enables a renewable resource – paper fibre – to be used again and again, as part of a closed loop recycling process for corrugated packaging.

With growing awareness of our impact on the environment and global targets aimed at tackling the issue, new processes, materials, design and technology have made it viable for manufacturers like us - and consumers - to embrace a new way of thinking.

That’s why our cardboard waste is recycled using a circular recycling model.

Our aim is to obtain a circular economy, where reduce, reuse and recycle is at the heart of every stage of our manufacturing process. The aim is to minimise the use of raw materials in our corrugated packaging whilst maintaining durable good and encouraging our customers to recycle and reuse too.

Pulp to cardboard

Our paper suppliers will create cardboard sheets from paper pulp and will produce sheets of cardboard to be cut, shaped and printed into stunning packaging solutions for our customers.

Transformation to packaging

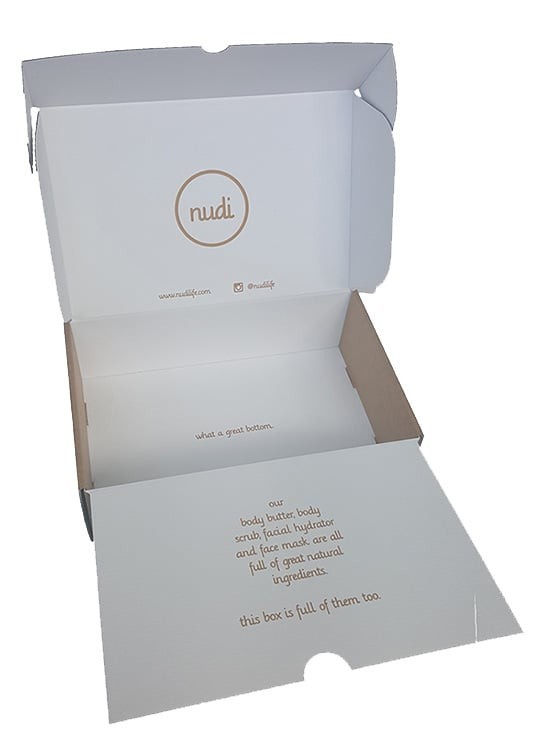

Once we receive the cardboard sheets, we go about working our magic and is cut, shaped and sometimes printed to produce stylish shelf and retail ready packaging for our customers.

Trimming off the waste

In our warehouse, we’ve installed a waste extraction system which is linked to each of our machines. This clever piece of machinery and collects cardboard off-cuts and waste produced during the manufacturing process and chops them up further through the extraction system.

Turning off-cuts into bales

The waste is then fed into our semi-automatic baler to create compact bales of offcut cardboard.

Where do the bales go?

The bales waste is then sold and collected by our board supplier who then converts it back into paper to be used in the cycle again! For every sale of once used cardboard box the demand for new boxes is reduced and this in turn reduces the demand for paper and energy. After reuse the box is still recyclable so the material can be reprocessed into paper after second use.

We’re constantly looking at new ways of improving our carbon footprint. In an effort to reduce the negative impact our work might have on the environment, we’ve adopted several changes within our factory and offices in a bid to create a more environmentally friendly company including:

Check out our environment page for more information and our latest updates.

Complete our quick enquiry form.

FAQ's

What are Belmont Packaging MOQ's?

Our MOQ starts from 1000 units depending on the size, style and material of the box.

How long does it take to receive a quote?

Once we have all the relevant information for your corrugated cardboard box requirements, we will aim to turnaround quotes within 24-48 hours.

However, complete bespoke designs will require longer including design time.

Check out some more FAQ's here!

This site uses cookies to monitor site performance and provide a mode responsive and personalised experience. You must agree to our use of certain cookies. For more information on how we use and manage cookies, please read our Privacy Policy.